What are the Types of Production System?

Manufacturing is the backbone of every industry, as it ensures that products are consistently available to meet consumer needs. The market performance of a company depends on its efficiency and effectiveness in the production strategy. The production systems determine the way that goods are produced, and this affects efficiency, cost, and scalability.

Various industries employ different production methods, depending on factors such as product variety, production volume, cost-effectiveness, and flexibility. A business environment needs to select the best production system that enables it to produce optimally and satisfy market needs.

This article examines the various types of production systems, their key characteristics, advantages, disadvantages, and relevant industry examples.

Learning about different production systems—like job shops, batches, mass, and lean methods—is a solid foundation. But turning that knowledge into a real-world strategy requires hands-on experience. Our Post Graduate Program (PGP) at Altera is designed to bridge this gap through industry-based projects and expert guidance. Visit the section on our main site to explore.

What is a Production System?

A production system refers to an organized process of converting raw materials (inputs) into finished products (outputs) through various manufacturing activities. It is the backbone of manufacturing and has been instrumental in enhancing the efficiency of resource utilization in the production of goods and services that meet market needs.

In simple terms, any production system can be modeled as a black box in which inputs (raw materials, labor, energy, and information) are channeled into the system and undergo different processes, after which end-products are produced. The conversion of the input to output can be done in different ways, and they include:

- Separating: Splitting one material into multiple parts (e.g., cutting a wooden plank).

- Putting Together: Assembling varying materials to make one product (e.g., putting furniture together).

- Detaching Shape: Utilization of materials to discard waste (e.g., carving wood with a lathe).

- Forming: Reshaping materials without waste (e.g., hammering metal into shape).

- Quality Adaptation: Improving the properties of products (e.g., surface treatment of metals).

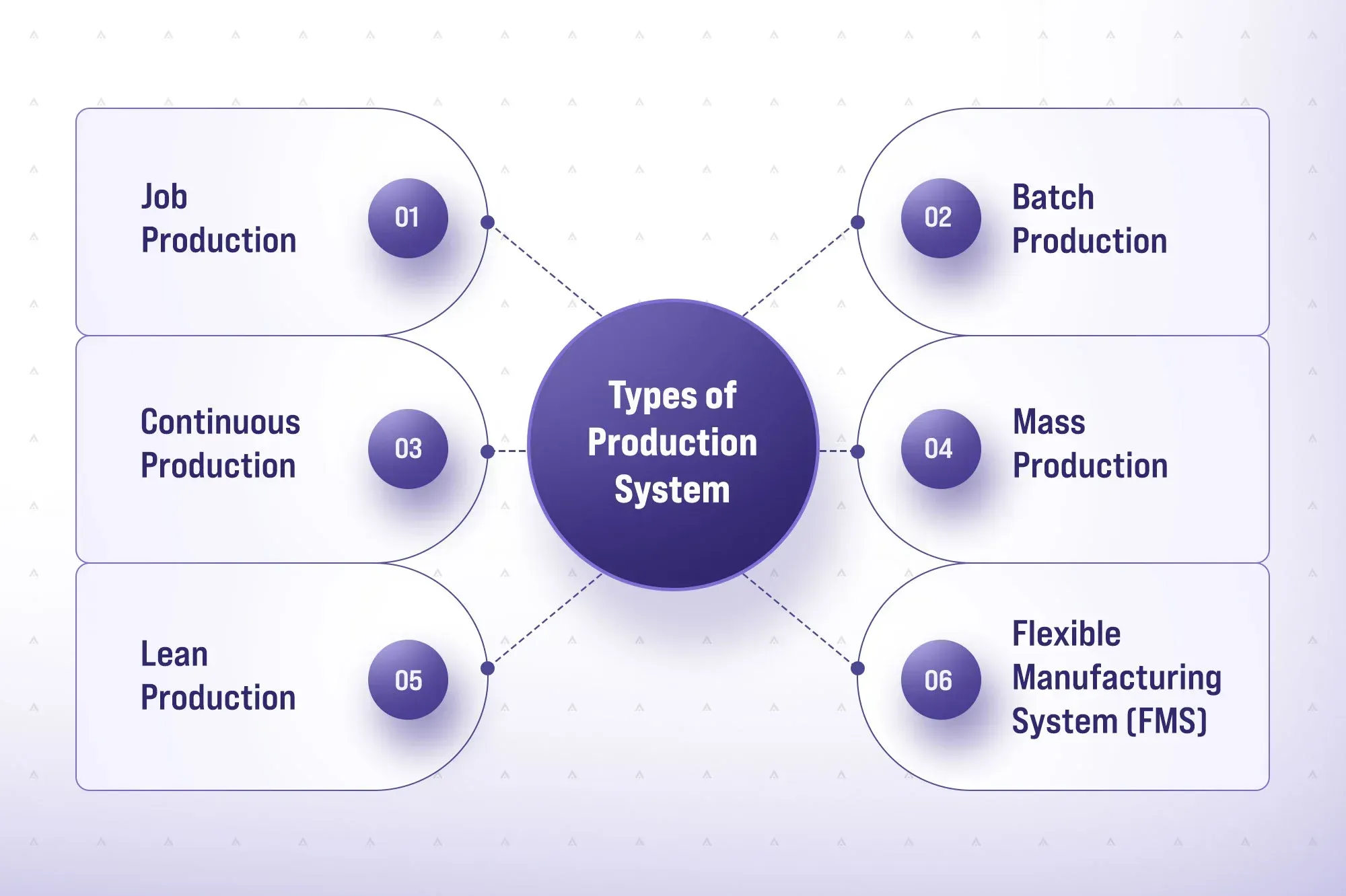

Types of Production Systems

Various industries use different forms of production systems in operations management, which are determined by the aspects of product demand, customization, and cost implications, as well as technological capacities. The main forms of production systems, along with their distinctive features, pros, and cons, are outlined below.

Job Production

Job production is concerned with the production of goods on a one-to-one basis or in small quantities, and sometimes based on the customer's specifications. This is an optimal system where products are customized, of high quality, and require specific skills and craftsmanship.

Characteristics:

- Every product is original and it is designed based on the needs.

- Production is labor-intensive, requiring skilled workers with specialized expertise in their respective crafts.

- The process is usually slow, as each item undergoes separate stages of production.

- Machinery and tools are versatile, enabling a wide range of production tasks.

- Very high flexibility in work schedules due to variations in product specifications.

Advantages:

- It enables extensive product personalization to cater to specific customer preferences.

- It also ensures a high level of quality by paying attention to detail in the production process.

- Employees acquire specialized skills, which lead to high craftsmanship.

- It is suitable for creating complex and advanced designs that are beyond the reach of mass production.

Disadvantages:

- Production is time-consuming, resulting in increased lead times.

- It is highly costly to produce because of the requirement for manual labor and customization.

- It is subject to low efficiency as machines and workers frequently switch tasks.

Examples:

- Custom furniture making

- Tailor-made suits

- Handmade jewelry

- Prototype development in the automotive industry

Batch Production

In batch production, a predetermined number of the same products are produced, and then a different production is started. It strikes a balance between flexibility and high-level optimization, which is ideal for medium-scale production.

Characteristics:

- Production is carried out in batches, with each batch undergoing a complete manufacturing process before the next batch begins.

- Machines and tools require reconfiguration between batches to accommodate different products.

- A moderate level of customization is possible while maintaining efficiency.

- More standardized than job production, but still allows some variation.

- Requires strategic scheduling to minimize idle time and optimize resource utilization.

Advantages:

- It reduces unit production costs in relation to job production by exploiting the benefits of bulk production.

- It grants some flexibility in product design and variations.

- It streamlines the use of the workforce and machinery, enhancing productivity.

- It promotes the uniform quality of each batch.

Disadvantages:

- Setup time between batches can lead to production delays.

- It requires storage space for work-in-progress inventory.

- It is less flexible than job production when it comes to fully customized products.

Examples:

- Baked goods (pastries, loaves, biscuits)

- Drugs and medical pills

- Clothing and textile products

- Journal publications and literature

Mass Production

Mass production is the large-scale production of standardized goods or commodities through fully automated processes. It is concerned with efficiency, cost-cutting, and uniformity.

Characteristics:

- Production is continuous, with products moving through an assembly line.

- Minimal customization is required, as products are standardized.

- Specialized machinery and workers are used to enhance productivity.

- Mass production lowers the unit cost of an item due to economies of scale.

- Uniformity of products is ensured through standardized quality checks throughout the process.

Advantages:

- It is the most efficient, as it provides large quantities at a low cost.

- It guarantees standardization and quality of products.

- It also involves minimal labor due to automation, and human error is minimized.

- It contributes to high market demand because it can produce at a faster rate.

Disadvantages:

- It involves a large start-up cost in equipment and facilities.

- It lacks flexibility and thus cannot easily change the product designs.

- It may lead to job dissatisfaction, as employees may be required to perform repetitive tasks.

Examples:

- Car production (e.g., Toyota, Ford)

- Manufacturing of Smartphones (e.g., Samsung, Apple)

- Home appliances (e.g., fridge, washing machine, etc.)

- Fast-food chains (e.g., McDonald's, Burger King)

Continuous Production

The 24/7 continuous production involves production with minimal interruptions, frequently used in industries where products must be produced in a continuous and uninterrupted flow.

Characteristics:

- The production is continuous, with no downtime, which means the supply remains uninterrupted.

- Highly automated systems that require minimal human intervention.

- Machinery is highly specialized in order to be efficient.

- Constructed with high output capacities.

- The strict quality measures ensure that all products are produced according to specifications.

Advantages:

- It is the most efficient with the least downtime.

- It assists in cost reduction of labor through automation.

- It has the ability to make homogeneous and repetitive products in large volumes.

- It is best suited in the industry where goods have to be supplied continuously.

Disadvantages:

- It is very capital-intensive in terms of infrastructure and technology.

- It is also not very flexible, and switching between products is a complex process.

- It requires regular maintenance and supervision to prevent any failures.

Examples:

- Oil refineries

- Power plants

- Manufacture of steel and cement

- Production of fertilizers, paints, etc. (e.g., chemicals)

Lean Production

Lean production focuses on minimizing waste and maximizing efficiency while maintaining high-quality standards. It aims to eliminate non-value-adding processes.

Characteristics:

- Emphasizes waste reduction to improve resource efficiency.

- Uses just-in-time (JIT) inventory management to reduce excess stock.

- Ongoing refinement (Kaizen) lies at the heart of this methodology.

- Promotes teamwork across departments to foster innovation and drive collaboration.

- Focuses on delivering value to customers.

Advantages:

- It helps reduce operational costs by eliminating unnecessary steps.

- It improves overall productivity and efficiency.

- It helps enhance product quality through continuous improvement strategies.

Disadvantages:

- It requires that the process be constantly checked and corrected.

- JIT inventory is closely dependent on the efficiencies of suppliers.

- This implementation process may be problematic in certain areas.

Examples:

- Toyota Production System

- Assemblies: consumer electronics.

- Custom-built computers (e.g., Dell-built computers).

Flexible Manufacturing System (FMS)

A Flexible Manufacturing System (FMS) is a combination of automation, robotics, and computerized controls that enable the creation of multiple types of products with high adaptability.

Characteristics:

- Utilizes CNC machines for ultra-precise fabrication.

- Seamlessly transitions between varying product lines.

- Minimizes delays during production changeovers.

- High efficiency while still allowing for some customization.

Advantages:

- It is quite flexible to product demands.

- It minimizes inventory expenses because of effective production planning.

- It makes the most of the automated technology, making it more efficient.

Disadvantages:

- It does not necessitate a large start-up capital for technology and equipment.

- It requires a well-trained human resource to operate automated systems.

- Maintenance and troubleshooting of this system can be a complicated process.

Examples:

- Aerospace industry (e.g., Boeing/Airbus)

- Car production (e.g., automated production lines in Tesla)

- Semiconductor manufacturing (e.g., high-tech industry)

FAQs

Q1. What are the three kinds of production systems?

Ans: There are three major production systems, namely:

- Job Production – It entails the production of single or highly customized goods to suit the specific needs of a customer. Example: Custom furniture making.

- Batch Production – Produces goods in specific quantities or batches before switching to a different product. Example: Bakery products.

- Mass Production – Focuses on massive and standardized production of items through automation. Example: Automobile production.

Q2. What are the four production processes?

Ans: The four key production processes are:

- Separating – This refers to a process in which an input is divided into two or more outputs. Example: Cutting the wood into two or more pieces.

- Putting Together (Assembly) – Combining different components to form a final product. Example: Assembling car parts.

- Forming – Reshaping materials without subtractive processes. Example: Metal shaping in manufacturing.

- Quality Adaptation – This is where the characteristics of an item are altered based on its durability, Appearance, or Future Usage. Example: Applying paint or coating to a metal surface.

Conclusion

The effectiveness, affordability, and scalability of manufacturing in various industries are largely determined by the production systems employed. Out of job production, which is customized-oriented, and mass and continuous production, which is efficiency- and high-output-oriented, each system is structured according to business requirements. Furthermore, lean and flexible manufacturing systems are innovative, as they ensure the optimization of resources and responsiveness to market changes.

With the rise of AI-driven production systems, industries are embracing intelligent automation to enhance decision-making and streamline operations. Understanding these production systems allows businesses to select the most suitable approach, ensuring maximum productivity and competitiveness in a rapidly evolving marketplace.