What is the Scope of Operations Management?

Operations management (OM) is one of the most crucial functions of any business, whether it is small or large, regardless of the sector or nature of its operations. In factories, service providers, and any other area, OM is important in ensuring that products and services are manufactured effectively to satisfy consumers.

Operations management is a very broad section that encompasses strategic planning, resource management, quality control, supply chain coordination, and customer satisfaction. OM contributes to organizational prosperity in the current competitive business world by ensuring there is a balance between efficiency, cost-effectiveness, and innovation.

Operations management plays a crucial role in ensuring businesses become efficient and competitive. Students at Altera Institute are taught how to use these principles in real-life situations, acquiring the abilities and confidence that enhance career opportunities and success in career placement.

This article examines the key areas that define the scope of OM, offering practical insights to help you understand its crucial role in real-world business operations.

Objectives of Operations Management

To manage the transformation of inputs (such as materials, labor, capital, and information) into valuable outputs, goods, and services, operations managers focus on well-defined objectives set through proper research that drive both short-term efficiency and long-term sustainability.

Below are the 8 key objectives of operations management:

Achieving Efficiency and Productivity

One of the primary objectives of operations management is to boost the efficiency and productivity of production management systems. This involves utilizing the available resources to the best of their ability by using raw materials, machinery, manpower, and time to produce as much as possible while minimizing waste.

Operations managers achieve this by streamlining work processes, removing inefficiencies, lessening delays, and ensuring that every production phase adds value. High productivity also results in reduced costs and revenue to the business.

Delivering Superior Quality

Quality is non-negotiable in today's competitive market. Operations management focuses heavily on delivering products and services that consistently meet or exceed customer expectations.

This is achieved through the implementation of effective quality control mechanisms, the adoption of quality improvement techniques such as Six Sigma or Total Quality Management (TQM), and maintaining a high level of compliance with industry standards. High-quality products not only increase client satisfaction but also enhance brand loyalty and reputation.

Controlling Cost and Waste Reduction

Minimizing and controlling production and operations costs is another significant objective. This is achieved by eliminating waste points, automating work processes, optimizing resource utilization efficiency, and implementing cost-effective production processes such as Lean Manufacturing or Just-in-Time (JIT) inventory control.

The long-term strategic objective is to save money and not to lose quality in order to provide a competitive price and keep the business afloat.

Meeting Customer Demand Effectively

The operational system of any organization should ensure that it can meet customer demand in the right quantity, quality, and within the specified delivery time. Operations managers are involved in capacity planning, production scheduling, and supply chain coordination, ensuring that customers receive the appropriate products when they need them.

Meeting demand reliably helps gain customer trust, retain clients, and avoid situations of stockouts or excessive inventory.

Improving Adaptability and Flexibility

Customer tastes, technology, and business conditions are ever-changing in a dynamic market. The design of production systems that can respond to these changes quickly is a primary objective of operations management. Whether it involves modifying production volumes, introducing new products, or adopting new technologies, operations managers strive to ensure that the organization remains agile and responsive.

Strengthening Supply Chain and Inventory Management

Modern operations management plays a crucial role in controlling the supply chain, which involves an interconnected system of vendors, producers, wholesalers, and retailers. A streamlined supply chain means that the materials are procured on time, there are no delays in the manufacturing process, and goods are delivered on time.

Effective inventory management also plays a vital role in avoiding excess stock, low holding costs, and stockouts, thereby ensuring a healthy balance between demand and supply.

Minimizing Risks and Disruptions

Operations managers operate proactively to determine, evaluate, and avert any possible risks that may interfere with production or service delivery. This involves dealing with supply chain uncertainties, equipment malfunction, labor problems, or unforeseen changes in demand. Operations management protects the organization against expensive disruption and delays in production by promoting risk management and contingency planning.

Promoting Coordination and Communication

Operational management is crucial in ensuring effective communication and coordination among departments, suppliers, employees, and other stakeholders. Fluent coordination will help all stakeholders involved in production align with shared business objectives.

Operations managers foster team spirit, promote cross-functional cooperation, and facilitate the free flow of information to enhance efficiency, reduce errors, and enhance decision-making.

By meeting these goals, operations management enables organizations to be more profitable, customer-focused, and adaptable to the dynamic business environment.

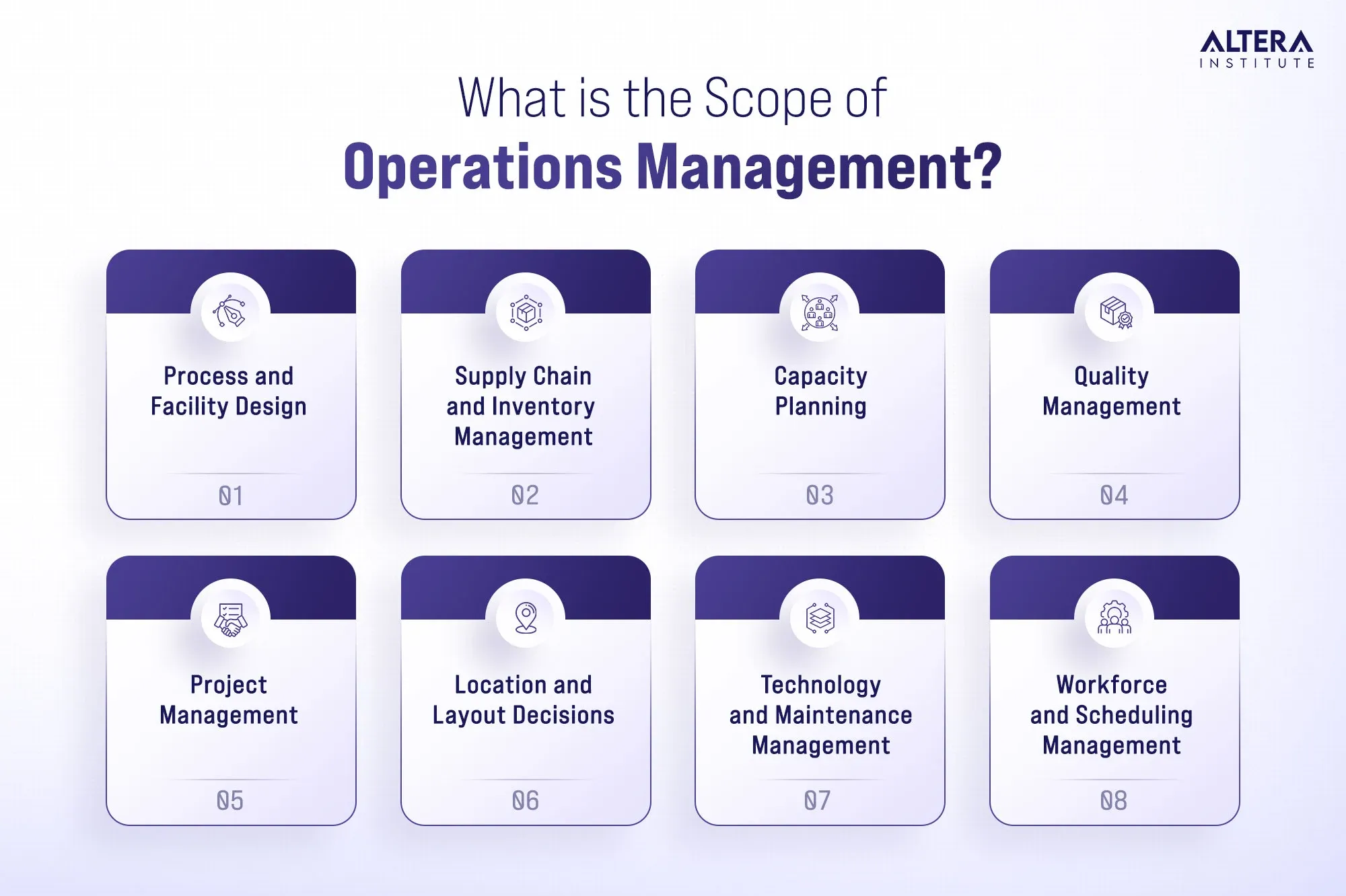

What is the Scope of Operations Management

The scope of operations management can be understood by the fact that it is applied to every stage of the production and delivery process. It applies not just to industrial production but is equally vital in service-based industries.

Operations Management encompasses eight major scopes, as listed below.

Process and Facility Design

The initial important area of operation management is to design processes and facilities that are necessary to produce. This includes organizing the production of products or services, identifying suitable methods of production, determining the choice of technology, and designing workflow patterns.

The purpose of process design is to create effective systems by eliminating waste, minimizing process time, and facilitating smooth operations. Facility design, on the other hand, entails the optimal positioning of physical spaces, equipment, and workstations to maximize productivity and minimize unnecessary movement within the facility.

Supply Chain and Inventory Management

Supply chain management governs the movement of goods, data, and funds from suppliers to consumers. Operations managers coordinate purchasing, logistics, warehousing, and distribution activities.

Inventory control is a significant feature of supply chain management that ensures the optimal stock level of both raw materials and finished goods. Effective inventory control helps decrease carrying costs, prevent stockouts, and satisfy demand without delays or overstocking.

Capacity Planning

Capacity planning is the calculation of the required production volume to satisfy the existing and emerging market needs. Operations managers determine the available resources, predict demand, and decide on the expansion, reduction, or alteration of production capacities to maximize efficiency.

It is also aimed at ensuring that the organization operates at a level that avoids either underutilization or overutilization of its capacity, thereby achieving a balance between cost-efficiency and responsiveness to demand fluctuations.

Quality Management

Another key responsibility is upholding product and service quality. Operations managers establish benchmarks, enforce quality checks, and drive ongoing enhancement initiatives, such as Total Quality Management (TQM) or Six Sigma.

Quality management ensures that products meet customer expectations, comply with regulatory requirements, and ultimately lead to customer satisfaction and a positive brand image.

Project Management

Project management plays a very critical role in the successful completion of operations, which might be the launching of a new product, the installation of new equipment, or the expansion of facilities. Project management entails planning, scheduling, resource allocation, and management of activities within a designated time period and budget.

Operations managers oversee multiple teams to deliver project objectives at the best cost, quality, and time.

Location and Layout Decisions

The location of facilities like factories, warehouses, or service centers is a very important consideration when making operations management decisions. Some of the major parameters that significantly influence the success of operations include proximity to suppliers and markets, transportation costs, labour availability, and infrastructure.

After the location is determined, operations managers begin working on the facility layout, integrating machinery, workspaces, and equipment to maximize space utilization, enhance work processes, and increase productivity.

Technology and Maintenance Management

Modern operations heavily rely on technology to streamline production, improve accuracy, and reduce costs. Operations managers are responsible for selecting, deploying, and overseeing technologies such as automation, enterprise software, and production systems.

Moreover, maintenance management involves routine checks, servicing, and repairs of equipment to avoid failures, minimize downtime, and ensure operational continuity.

Workforce and Scheduling Management

The human factor plays a very important role in operations. Workforce planning involves the recruitment, training, and management of employees in a manner that ensures the presence of adequately skilled personnel to meet production needs.

Scheduling, conversely, is the process of planning work schedules that balance the workload, reduce idleness, and adhere to deadlines. Effective workforce and scheduling management leads to improved employee performance, reduced labor costs, and the timely delivery of goods and services.

Components of Operations Management

Operations management (OM) is a complex set of interdependent components that collaborate to achieve smooth production and service delivery. The ability of these elements to coordinate is what determines a company's success.

Operations management comprises 12 main elements, as illustrated below:

Forecasting

Forecasting assists the managers in predicting the future requirements of production by examining the past trends, market data, and historical records. It plays a crucial role in determining the best production of goods or services.

Proper prediction avoids overproduction, which leads to excessive inventory, and underproduction, which results in lost sales. Through predictive customer demand, organizations can maximize their production schedules and resources.

Location Strategy

The selection of an ideal place to set up manufacturing plants, warehouses, and service units is a critical variable that can have a significant effect on the achievement of operations. It considers the availability of raw materials, the availability of skilled labor, the cost of transportation, accessibility to the customers, and the infrastructure. A good location strategy may help in lowering the cost of operation, speeding the delivery process, and serving the long-term objectives of the organization.

Maintenance Management

This dimension is involved with the maintenance and services of machines, equipment, and production systems. Periodic service will diminish chances of sudden failure in the equipment, improve working conditions, and also make machines work in their best condition. Proper maintenance prevents asset degradation and helps maintain overall production, resulting in cost reduction and enhanced productivity.

Purchasing

Purchasing or procurement involves obtaining the necessary inputs, parts, and services required for the production process. Companies are free to either practice centralized purchasing (purchasing done by a central department) or decentralized purchasing (purchasing done by respective branches or departments).

An efficient purchasing system will also ensure the timely availability of materials, facilitate a better bargaining process with suppliers, and reduce production delays due to material shortages.

Scheduling

Scheduling can be defined as allocating tasks, jobs, or production runs to the relevant equipment or workforce. When properly created, a schedule ensures that production deadlines are met without exceeding resources. Timely scheduling minimizes waste time, shortens the production process, and enables punctual fulfillment of delivery schedules. This results in improved use of machines, labor, and other resources.

Total Quality Management (TQM)

TQM is an ongoing improvement strategy that aims at customer satisfaction, where all employees participate in process improvement. Instead of merely inspecting the quality of the finished goods, TQM focuses on improving the production procedures and mechanisms to minimize the flaws and boost efficiency. This is aimed at delivering reliable outputs that not only meet but also exceed customer needs.

Materials Requirement Planning (MRP)

MRP is an organized approach to having materials available at the right time and in the right amounts to aid manufacturing strategies. It entails inventory analysis, calculating the extra material needs, and organizing the procurement or production. MRP assists organisations in preventing delays in production due to shortages of raw materials, as well as preventing unnecessary surplus inventory.

Quality Assurance

The foundation of operations management is quality. Quality control guarantees that the outputs are within a set benchmark. Through quality assurance, organizations develop confidence and a relationship with customers in the long run. Effective quality control systems result in fewer errors, reduced waste, and increased customer satisfaction.

Just-In-Time (JIT) Production

JIT refers to a system in which materials, components, and products are produced or purchased only when needed, as opposed to being stored in large quantities. This strategy helps to reduce inventory expenses, minimize the work-in-progress (WIP) inventory, and enhance the movement of material in the production process. JIT is aimed at optimizing, reducing waste, and meeting customer orders at the optimal time.

Process and Performance Analysis

This aspect focuses on evaluating the efficiency of production systems and processes. Managers compare the planned production goals with actual performance in terms of capacity utilization, efficiency, and output level. Gaps and inefficiencies that companies identify can be used to determine where performance can be improved and provide solutions to address these areas.

Facility Layout Planning

Facility layout involves the physical arrangement of equipment, workspaces, and storage facilities to optimize workflow. An efficient design minimizes unnecessary material flow, reduces production cycles, and promotes the effective utilization of space and workforce. It also helps minimize production cycles and increases output.

Inventory Management

Inventory management involves monitoring and controlling the flow of raw materials, semi-finished goods, and finished products. Strategic inventory management prevents both stock surpluses and shortages. Maintaining optimal inventory levels helps organizations meet customer demand promptly while minimizing holding and storage costs.

What Are the Roles of an Operations Manager?

An operations manager is pivotal in supervising and refining production and service marketing processes. Their primary duty is to ensure that daily operations align with business objectives while running smoothly. The key roles of an operations manager include:

- Enhancing existing systems, processes, and best practices to boost productivity and operational efficiency.

- Monitoring and managing production or service processes to ensure smooth operations and achieve the desired quality of output.

- Handling budgets to ensure optimal use of financial resources while maintaining cost-effectiveness.

- Leading the operations team by assigning tasks, setting deadlines, monitoring employee performance, and fostering a positive work environment.

- Managing material sourcing, stock planning, and warehousing to maintain smooth supply chain activities.

- Developing and nurturing partnerships with suppliers to fulfill organizational requirements efficiently.

- Performing risk evaluations and deploying mitigation tactics to lessen operational vulnerabilities.

- Comparing financial and operational indicators to identify opportunities to increase profits and cut costs.

- Ensuring product quality through regular inspections and evaluating performance metrics.

Overall, an operations manager has the role of maximizing resources, enhancing processes, and human resources to achieve operational excellence.

FAQs

Q1. What are the 7 major operations management functions?

Ans: The seven major functions of operations management are the following:

- Process Design - The process of designing an efficient production process.

- Capacity Planning - Adjusting demand to production capacity.

- Inventory Management- Management of raw materials, WIP, and finished products.

- Supply Chain Management - Organizing the flow of resources and information.

- Quality Management - Ensuring compliance with quality in products and services.

- Scheduling - The ability to plan production schedules.

- Maintenance Management- Ensuring that equipment operates smoothly with minimal downtime.

Q2. What is the scope of operations of a company?

Ans: The scope of operations of a company refers to all operations that are involved in the production and delivery of goods or services. It includes:

Product and process design

- Production management

- Supply chain and logistics

- Inventory and quality management.

- Maintenance

- Ongoing improvement efforts.

Q3. What career scope does an MBA in operations management offer?

Ans: MBA in operations management trains the professional to work in production, supply chain, logistics, quality management, and project management. It opens up opportunities in areas such as manufacturing, retail marketing, healthcare, IT, and consulting, with some of the positions including operations lead, logistics coordinator, and project supervisor.

Summing Up

Operations management is the foundation of any successful organization, as it is crucial for transforming inputs into valuable outputs with efficiency, quality, and customer satisfaction. It is extremely broad, encompassing process design, capacity planning, supply chain management, and quality control.

In the current competitive and dynamic market, efficient operations management is crucial for achieving business goals, maintaining profitability, and delivering superior customer value.

Whether you are a student, a manager, or an aspiring operations professional, understanding the principles, functions, and scope of operations management is key to driving sustainable success in any industry.